Micro FlexPro

Ultrafast Laser Processing Machine

The Micro FlexPro laser processing system offers innovative solutions for high-speed laser processing of medical materials.

The Preco ST1000 laser machines come with Preco's user-friendly AcuNav® user interface and are designed for multi-axis laser welding, heat treating, cladding, drilling and cutting of metallic components. These systems are designed for manual part loading, however automated part load/unload options can be integrated.

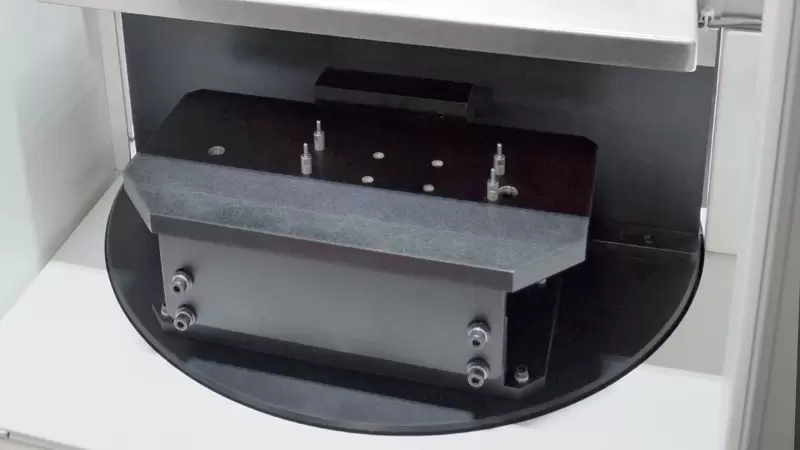

The ST1000 features a two-position index table to allow small part load/unload to take place during the laser processing cycle resulting in high productivity.

Just some of the many benefits of buying a Preco ST1000 medical laser machine.

For single side or pass-through automation

The ST Series readily accepts linear motors and encoders in the X and Y-axis

To optimize you specific application, any laser manufacturer, wavelength or power level can be integrated into the ST Series production line

Additional Z-axis travel is available for large parts

For single side or pass through automation

Designed for automation and to minimize operator fatigue

Rotary and rotary/tilt tables are easily integrated into the ST Series Workstation. Worm drive or direct drive rotary stations can be supplied.

Manual or programmable tilt-heads are available

Preco can design and build tooling specific to your processing needs

A range of options are available from simple CCTV devices for manual part alignment to integrated vision solutions that automate seam or part alignment

Technical parameters are based on a baseline standard but all Preco laser machines can be customized to meet your product's needs.

| Machine Footprint* | Width: 890 mm (35 in.) |

| Depth: 1400 mm (55 in.) | |

| Height: 2160 mm (85 in.) | |

| X-Y-Z Travel | 300 mm x 150 mm x 100 mm (12 x 6 x 4 in.) |

| Accuracy** | ± 25 μm (± 0.001 in.) |

| Speed*** | 12.7 m/min (500 in./min) |

| Safety Enclosure | Class 1 |

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

*Enclosure dimensions exclude the HMI, laser chiller and other periphery devices

**Accuracies are per 300 mm or 12 in. of travel. Higher accuracy tables are available as an option

***High speed linear motor drives available as an option

The Micro FlexPro laser processing system offers innovative solutions for high-speed laser processing of medical materials.

The Mini FlexPro® laser processing system offers innovative solutions for high-speed laser processing of flexible circuits.

The WebPro Ultrafast digital laser cutting machine is rapidly re-configured for changing medical job requirements.

This medical laser system features a two-position index table to allow small part loading and unloading during the laser processing cycle

This laser welding machine offers cost-effective and innovative solutions for high precision laser welding of medical device components

The need for the highest yields and production rates calls for rotary die cutting medical applications.

The need for the highest yields and production rates calls for rotary die cutting that delivers flexibility and speed.

One of Preco's dedicated professionals will be in touch to help with your interest in the ST1000 laser machine.

715.247.3285 | Email