One Partner, Two Paths to Production:

Pioneer Breakthrough Performance

Lead the future of your industry with Preco. Engineer your total solution here with laser and die-cutting applications development, capital equipment, and contract manufacturing services that meet you anywhere in your process. With a global service network, Preco leads our industry in speed, reliability, quality, and service – and we succeed at engineering what others cannot to put enterprises like yours at the forefront of the future.

SOLUTIONSPush the Boundaries of Possibility

Position your business at the forefront of the future. We understand your rapidly changing marketplace and deliver solutions to help you lead – while increasing efficiency, reliability, scalability, and supply chain stability.

Flexible Packaging

Laser processing and die cutting

Advanced Energy

Sustainable energy production solutions

Aerospace & Defense

Commercial, space and defense

Abrasives

From micro-polishing to heavy grits

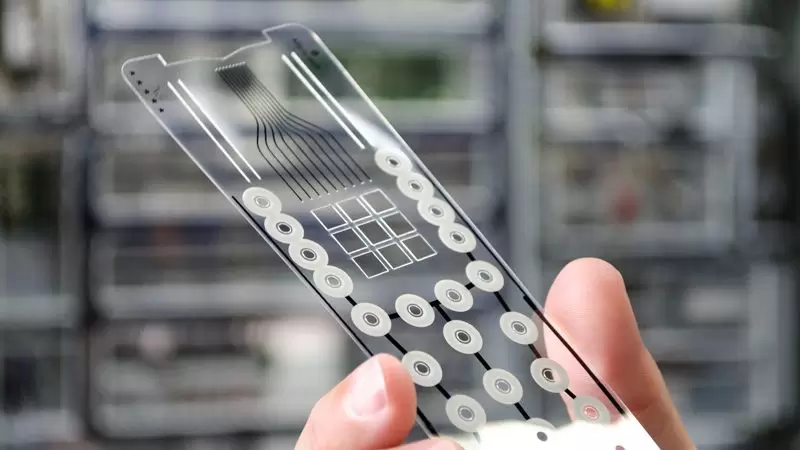

Electronics

Smaller, faster, smarter laser technology

Medical

Advanced processing solutions

TESTIMONIAL

"We took on an aggressive challenge and our success could not have been possible without Preco's teaming and performance."

– Mike Humble, Nammo Composite Solutions

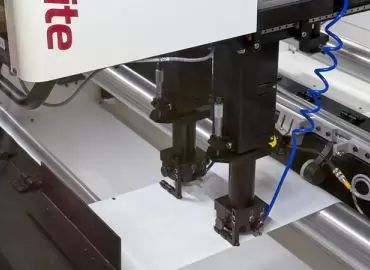

Converting Ideas Into Innovation

Preco pioneers laser, flat bed and rotary die-cutting equipment solutions for advanced material processing. A global designer and manufacturer of high-speed, high-accuracy automated processing systems, Preco also leads as a laser integrator offering cutting, perforating, welding, and other specialized industrial processing applications.

With proprietary die cutting and laser-based manufacturing capabilities, Preco is one of the largest contract manufacturing service providers in North America – partnering with innovative enterprises to provide future-proof laser cutting, scoring, perforating, welding, cladding, heat treating and die cutting services.

Preco News See All

The Largest Service Network Globally

Get a partner in growth – from applications development and training to remote diagnostics and technical field service – and stay at peak production and performance.