Micro FlexPro

Ultrafast Laser Processing Machine

The Micro FlexPro laser processing system offers innovative solutions for high-speed laser processing of medical materials.

The Mini FlexPro® laser processing machine offers innovative and cost-effective solutions for high-speed laser processing of medical devices, membrane switches, digitally printed products, flexible circuits and much more.

Speed and versatility.

The Mini FlexPro laser system provides the speed of galvanometer processing with the versatility of an XY positioning system, allowing for high-speed processing and part movement without any compromise in part quality.

Mini FlexPro's non-contact laser process eliminates tool and die fabrication, maintenance and storage costs. This also ensures a superior edge quality with no burrs, debris or strands left on the cutting edge.

Just some of the many benefits of buying a Preco Mini FlexPro laser machine.

Larger sheet and part sizes cut with higher precision and better quality

Provides uniform processing independent of cut shape and processing speeds

Programmable vacuum control during the load and unload process

Single or dual cameras for X-Y-Ø positioning of the cut pattern to material features

Saves programming time because large cut fields are automatically segmented to fit current field-of-view

Reduces set-up time; consistent production from operator to operator

Configured to accept various laser wavelengths and power based on the material to be processed

Allows for the field of view (FOV) adjustments without changing optics

Customization options to accept a variety of sheet loaders and unloaders

Multifunctional option allowing for processing rolls up to 150 mm (6 in.) wide

Technical parameters are based on a baseline standard but all Preco laser machines can be customized to meet your product's needs.

| Machine Footprint | Width: 914 mm (36 in.) |

| Depth: 2 m (78 in.) | |

| Height: 2.4 m (95 in.) | |

| X-Y stage (Servo Driven) | 305 x 610 mm (12 x 24 in.) |

| Lower Vacuum Work Support | Included |

| Laser Wavelengths | 355 nm, 532 nm, 1 µm, 9.3 µm, 10.2 µm or 10.6 µm |

| Safety Enclosure | Class 1 |

| AcuBeam™ Software | Windows® based with full graphical / CAD interface |

| Password Protection | 2-Levels: Administrator & Operator |

| Laser Power | 10 - 450 Watts (Other laser sizes available per request) |

| Power Requirements* | Controller & Chiller (Int) - 380-420 VAC, 3 PH, 50 Hz |

| Controller & Chiller (US) - 200-230 VAC, 3 PH, 60 Hz |

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

* Laser Chiller may be powered separate or by laser system.

The Micro FlexPro laser processing system offers innovative solutions for high-speed laser processing of medical materials.

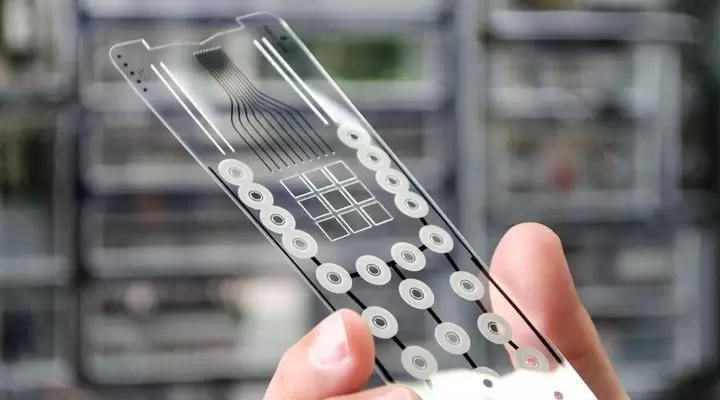

The Mini FlexPro® laser processing system offers innovative solutions for high-speed laser processing of flexible circuits.

The WebPro Ultrafast digital laser cutting machine is rapidly re-configured for changing medical job requirements.

This medical laser system features a two-position index table to allow small part loading and unloading during the laser processing cycle

This laser welding machine offers cost-effective and innovative solutions for high precision laser welding of medical device components

The need for the highest yields and production rates calls for rotary die cutting medical applications.

The need for the highest yields and production rates calls for rotary die cutting that delivers flexibility and speed.

One of Preco's dedicated professionals will be in touch to help with your interest in the Mini FlexPro laser machine.

715.247.3285 | Email